13 JAN 2018

INR 3,00,000/-

Lacquering is done to impart corrosion resistance Tin Cans used for storing food items. Solutions are invited for online lacquer viscosity measurement and auto viscosity correction system.

Challenge Details

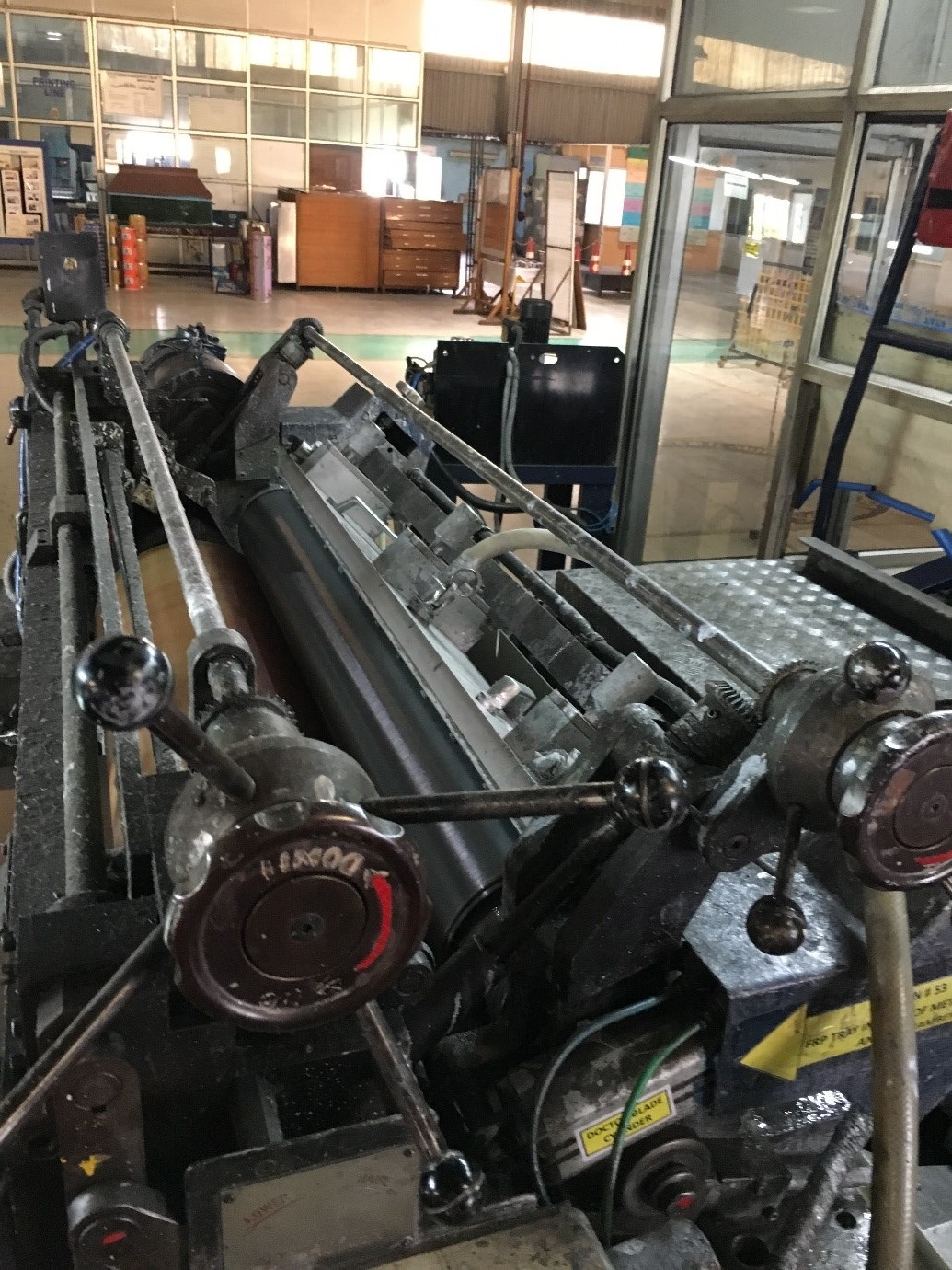

Lacquering is done to impart corrosion resistance to Tin sheets that are used to fabricate Tin Cans used for storing food items. Lacquering is performed after passivation of Tin coated steel sheets. The passivated sheets are lacquered by passing the sheets through two rolls which apply the lacquer on the sheet (fig. 1). The lacquering fluid is continuously fed to the top roller from a tank that stores the (viscosity controlled) lacquering fluid. This is a closed loop circuit (fig. 2). The sheets are dried after lacquering in a temperature controlled oven to get a uniform coating of lacquer. In order to maintain consistency of the film, viscosity of the lacquer has to be maintained within the desired norms which is typically 85 +/- 15 sec at room temperature, as measured by Ford cup (fig. 3). Viscosity measurement by Ford cup is shown in this video: https://www.dropbox.com/s/6q7hmd3s5ym8onb/IMG_7417.MOV?dl=0

The viscosity of the lacquer keeps changing during the process. It is measured after every 30 minutes using Ford Cup. If the viscosity is found to be within the acceptable limits as per the guidelines (85 +/- 15 sec), no action is taken. However, thinner is added, if the viscosity is on the higher side, and lacquer is added if the viscosity is on the lower side.

Currently, viscosity measurement is manual in nature. It is measured using Ford Cup at room temperature. At times, minor changes in the viscosity goes unnoticed, especially when it is near the boundary conditions.

An online lacquer viscocity measurement system was tried in the past to over come the problem. The system was used to measure viscosity but could not be used to correct the viscosity automatically.

Solutions are invited to solve the challenge. Following are the requirements of the new system.

- Automatic & continuous measurement of viscosity

- Automatic corrective actions to control the lacquer viscosity by adding more lacquer or thinner depending upon the deviation of viscosity measured. The viscocity measurements is to be done at room temperature (30 oC)

- The designed system should not make any marks on the metal surface while carrying out the measurements

- It should be easy to maintain. All the parts should be available locally in India.

- The integration of the system with the existing setup must be simple and should not require any major changes.