Challenges

Detection of black zones in a heat treatment furnace

Short Description:

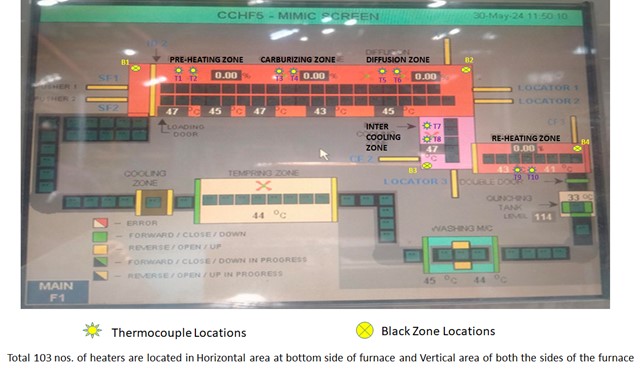

Looking for a solution to identify, in real time, a black zone (temperature difference) formation in any particular zone of the furnace.

Challenge Details

Automotive parts are heat treated in a continuous heat treatment furnace, which has five different zones: preheating, carburizing, diffusion, intermediate cooling and hardening zone. The parts heat treated should have desirable metallurgical properties and it is thus important to maintain uniform temperature inside the furnace by ensuring that the heaters are working continuously to ensure ‘no black zone’ inside the furnace. The furnace has a total of 100+ induction heaters, connected in parallel and temperature data is used for controlling the heaters. Thermocouples placed in each zone are used to measure temperature.

Currently, there is no real-time system to identify the malfunctioning of the heaters. as the temperature does not change even if one or two heaters stop working. This may create a localized black zone affecting the quality of parts that passes through this black zone area. All measures such as checking the quality of parts post the heat treatment, calibration of thermocouples etc. are reactive in nature and cannot help detect working condition of the heaters.

we are therefore seeking for solutions which can detect and alert malfunctioning of heaters (black zone) in real-time, so that corrective measures can be initiated.