Challenges

Elimination of manual intervention in managing Water Troughs/Channels

Short Description:

U shaped ‘Troughs’ or ‘Channels’ are created for holding water to act as a ‘sealant’ to avoid gases escaping. Water needs to be maintained at a level in these channels. Dust particles fall into the channels as they are not enclosed. Dust particles may absorb water and make the channels dry causing the gas to escape. Solutions are invited to automate the cleaning of channels which is carried out manually now.

Challenge Details

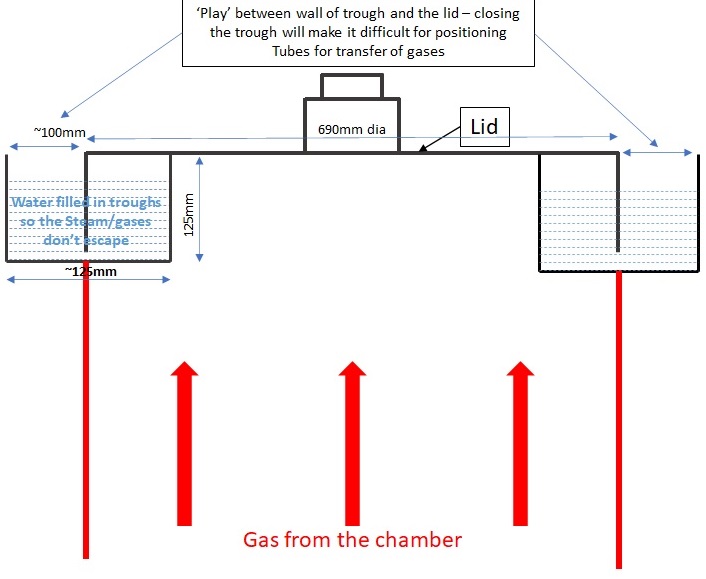

U shaped ‘Troughs’ or ‘Channels’ are created for holding water to act as a ‘sealant’ to avoid gases escaping (Please refer Figure 1). These channels surround the outlet which is closed with metal Lids (SS 304) of 10mm thickness. The channels are open to air and dust particles (of size 10-20 PM) fall into it. If the channels are left uncleaned, the accumulated dust particles create hinderance for closing the lid and may absorb the water leaving the channel dry and the gas may escape through the gaps. It is thus, necessary to ensure that water is always present in the Channels. Cleaning of channels is thus necessary and curently it is done manually and there are 176 channels in total. During the process of cleaning, operators may come in contact wth hot water (~70-80 Deg C) or the hot metal lid (~100 Deg C) and may run the risk of burn injuries.

Solutions are invited to clean the channels without manual intervention. Solutions which can replace or avoid water as a sealant or reduce the temperature of water are also welcome. Please note that options such as closing the channels (protection from dust) are NOT feasible as it makes it difficult (less clearance) to close and open the Lid. Please see Figure 1 which shows the schematic of the outlet and channel in cross section. Also, applying Sealants to the gap may not be feasible as the Lid (closing the outlet) is opened and closed very frequently.