INR 300000/-

18 Mar 2025

Challenge details:

In watch case manufacturing, the ‘case center' is an integral part of the watch. The case center is made with Brass, aluminum, and stainless-steel materials. The manufacturing process involves ‘press forming' operation (refer Figure 1). Forming is an operation where a blank (component - pre-formed case center) is pressed between a set of dies (with specific shape) to produce a finished or semi-finished part.

Sequence of tasks performed, during the forming operation, are as below:

- First, the component placed on a platform with its ‘Glass side' facing down. Then it is rotated so that the top view (geometrical view) matches with that of the die profile.

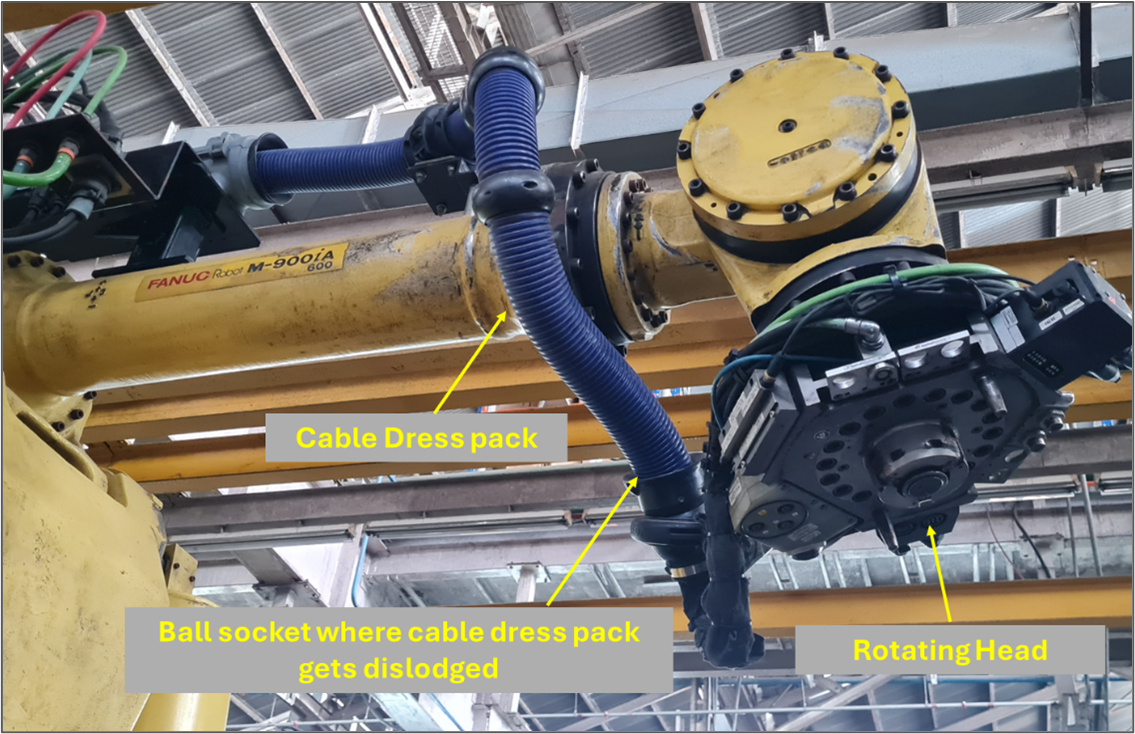

- Then a robot equipped with a central locator (part of gripper assembly, shown in Figure 2) picks up the component and places it on top of the die. It is critical to ensure that the component does not change its orientation when it is picked up and placed. This is currently taken care of, by the center locator.

- The placement of the component is checked (by using a scanning camera) and if found right, the forming operation begins. If the placement or orientation is not correct, then the same Robot picks up and rejects the part. The process of pick and place will begin again with the above 2 steps performed again.

Forming process, being a precise operation (100 microns tolerance on the die profile), accurate placement of the component is critical. Thus, special care must be taken to place the component correctly on top of the die. Currently, a special central locator is used for ensuring the component does not change its orientation. Since there are many variants of these components, it becomes difficult and time consuming to change the gripper to suit different variants of the component, assuming, we have as many grippers as the number of components. However, there are around 1000+ variations in size and shape and thus difficult to a. manufacture as many grippers b. managing the inventory and c. increasing the changeover time.

- Key metrics the gripper should satisfy for the

- Gripping solution to accommodate all variants.

- Gripping solution with a maximum height of 40 mm

- Easily adjustable during changeovers

- Further details on part

- Weight - min of 70 gm to 200 gm

- Size - 20mm min to 45 mm max

- Payload of Robot - 2 kg (Extended arm 450mm length)

We are looking for a solution for standardized gripping mechanisms (covering all the size and shape of the component) which will enable picking up the component and placing it in the die with perfect alignment and orientation.